+86 10 8467 3566

+86 10 8467 3566

Apr. 15, 25

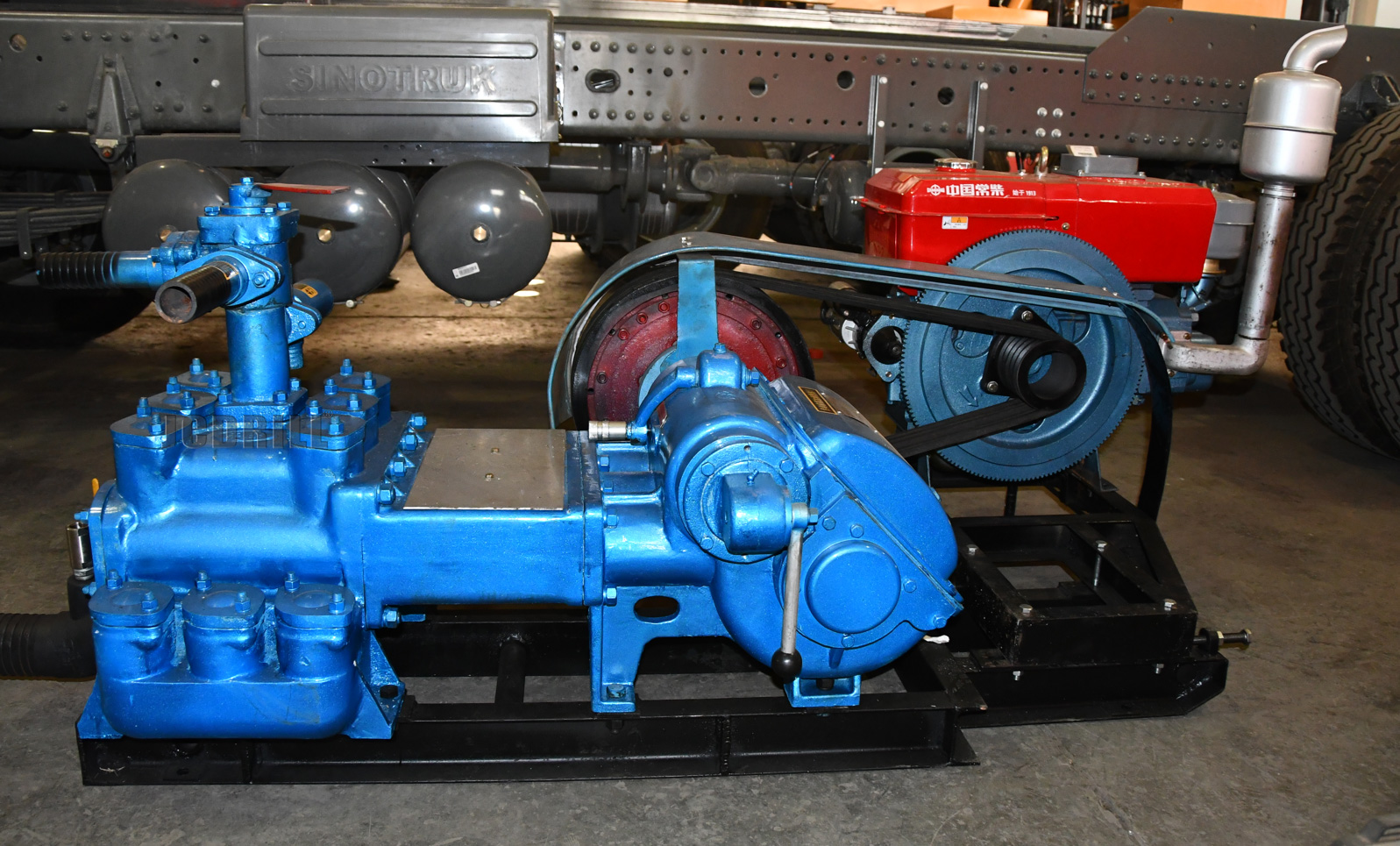

The life of mud pump is closely related to type selection, operation specification, maintenance and working condition adaptability. Systematic management can significantly improve the durability of equipment, as follows:

1. standardize the operation process

① Check before starting

-Check that the water inlet/outlet pipe is blocked. Ensure that the suction pipe, bottom valve, and pump body are full of water. Fill the pressure gauge buffer with lubricating oil .

-Verify the flexibility of the clutch, confirm that the hand rotating piston has no resistance, and the line insulation can be started before reaching the standard .

② Operation control

-Equipped with high pressure clean water pump (pressure > mud pump working pressure) to wash the packing to prevent seal wear .

-Monitor mud sand content ≤10%, stop cleaning immediately when exceeding the limit, to avoid particulate accelerated cylinder liner and impeller wear .

-Multi-gear pump switch different speed operation per shift, single gear running time ≥30 seconds to ensure uniform splash lubrication .

③ Shutdown management

-After long-term outage, disassemble the pump body, thoroughly remove residual mud, apply anti-rust oil, and store in dry environment

2. systematic maintenance

① Maintenance of wearing parts

-The seal ring is replaced every 3 months, and the cylinder liner/piston is tested for wear every 2000 hours (> 0.5mm needs to be replaced).

-The clearance between the impeller and the protection plate is controlled by adjusting screws of the rear bearing body. The standard value is referred to the equipment drawing (usually 0.5-1.2mm) to avoid vibration damage .

② Lubrication and cooling

-The power end gear box is lubricated every 500 hours, and the cross head tie rod is greased every shift .

-Check the cleanliness of cylinder liner cooling water every week. Clean the radiator when the water temperature is greater than 60 ° C to prevent high-temperature ablation .

3. fault prevention and technology upgrade

① Exception response mechanism

Stop immediately if vibration or abnormal response occurs during operation, check impeller blockage, bearing wear or clearance imbalance .

② Anti-wear modification

In hard rock operation, tungsten carbide coating is sprayed on the surface of the piston, which can increase the life of 40%; Optimize the coaxiality between the crosshead and the middle tie rod (error ≤0.05mm) .

③ Intelligent monitoring upgrade

Add pressure, temperature sensor, real-time monitoring pump efficiency data, combined with frequency control technology to dynamically adjust pump speed

JCDRILL mud pump with high wear-resistant material and intelligent working condition adaptation technology as the core advantages, significantly extend equipment life and improve work efficiency; And there are professional technical personnel can provide after-sales service to ensure that customers work worry-free. Choose professional quality and save long-term investment - JCDRILL uses core performance and reliable service to make every meter of drilling more worthwhile!

Previous: None

Next: JRC300: A Remote-Controlled Reverse Circulation Drilling Rig