+86 10 8467 3566

+86 10 8467 3566

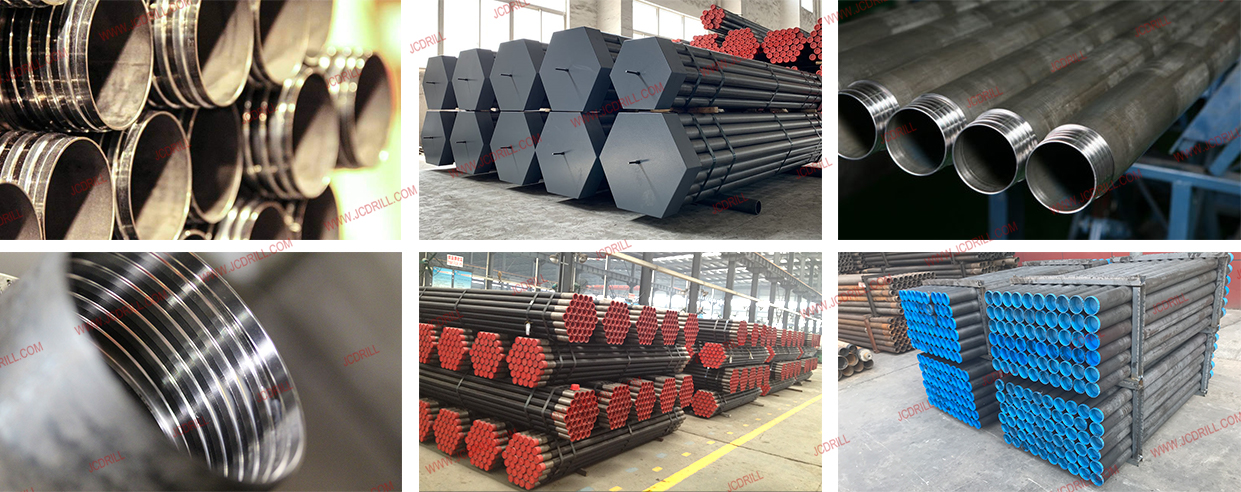

Type: Core Drilling Rod

Size: BW,BQ,NT,NHD,BTW, etc.

>> Application

This wireline drill rod is the equipment that connects the drilling tools and drilling bits, and it is mainly used to transmit power. It mainly consists of a tubing body and two thread ends.

Share

PRODUCT DESCRIPTION

The wireline drill rod features good wear resistance, optimal tensile strength capacity and good torsional property.

Concerning the packing, it is packaged by iron belts.

>> Characteristics

Drill Rod is used to manufacture a multitude of tools used for working other materials. The specifications of the initial Drill Rod required will be determined by the final use of the product and can be broadly defined into the following three categories:

Water Hardened Drill Rod is the most common type and is easily machinable due to the low alloy content. Drill Rod that has been water hardened is hard and durable but not suitable for welding, with typical applications including the manufacturing of hammers and files, machine parts, chisels, drills and razor blades.

Oil Hardened Drill Rod can be both machined and welded and is typically tough and durable. Typical applications include general woodworking and machining tools, knives, punches, and dies.

Air Hardened Drill Rod contains the highest alloy content making it hard and resistant/ It is commonly used to create specialized tools including gauges, punches, and shears.

Further specialized applications include shock resistant Drill Rod for the manufacturing of high impact tools such as jackhammer bits, hot working Drill Rod for high temperature applications and high speed Drill Rod for applications such as power saw blades.

>> Specification

| Thread type | Drill rod OD mm | ID mm | Heat treatment | Raw material | Designed hole depth | |

| S56 | 53 | 44 | China standard | 1000m | ||

| S59 / S75 | 55.5 71 | 46/61 | China standard | 45MnMoB | 1000m/1002m | |

| S95 | 89 | 79 | China standard | 600m | ||

| S75/AS95A | 61/79 | heat treatment the Thread | 45MnMoB | 1500m/1300m | ||

| CBH/CNH/CNH (T) | Both side were enhanced | 44/61/61 | Factory standard | Heat treatment the whole pipe | 30CrMnSiA XJY850 | 2500m/2300m/3000m |

| CHH | 78 | 30CrMnSiA | 1800m | |||

| CSH | 127 | 114.3 | S135 | 3000m | ||

| BQ | 55.6 | 46 | 2000m | |||

| NQ | 70.5 | 60.5 | DCDMA | Heat treatment the whole | ZT850 | 2000m |

| HQ | 89 | 77.8 | standard | pipe | 1500m | |

| PQ | 114.3 | 103.2 | ZT520 | 800m |

>> Stock

TAGS: